The essence of a chemical reaction is the process of breaking old chemical bonds and forming new ones, and the reactor is the carier of thechemical reaction, providina the necessary space and conditions for the reaction, As long as there is a place for reaction. the reactor is indispensable. The current reactors are even more diverse. They are widely used in the fields of medicine and food, chemicals, rubber, pesticides, dyes, etcThey are vessels used to complete processes such as vulcanization,nitration, hydrogenation, akylation, polymerization, and condensation. We specialize in the production of chemical reaction series containers. it hasreactors that can be adapted to varous reactions, and provides eauioment and technical services to university laboratonies, corporate R&D andchemical plants.

Continuous Flow Microchannel Reactor:

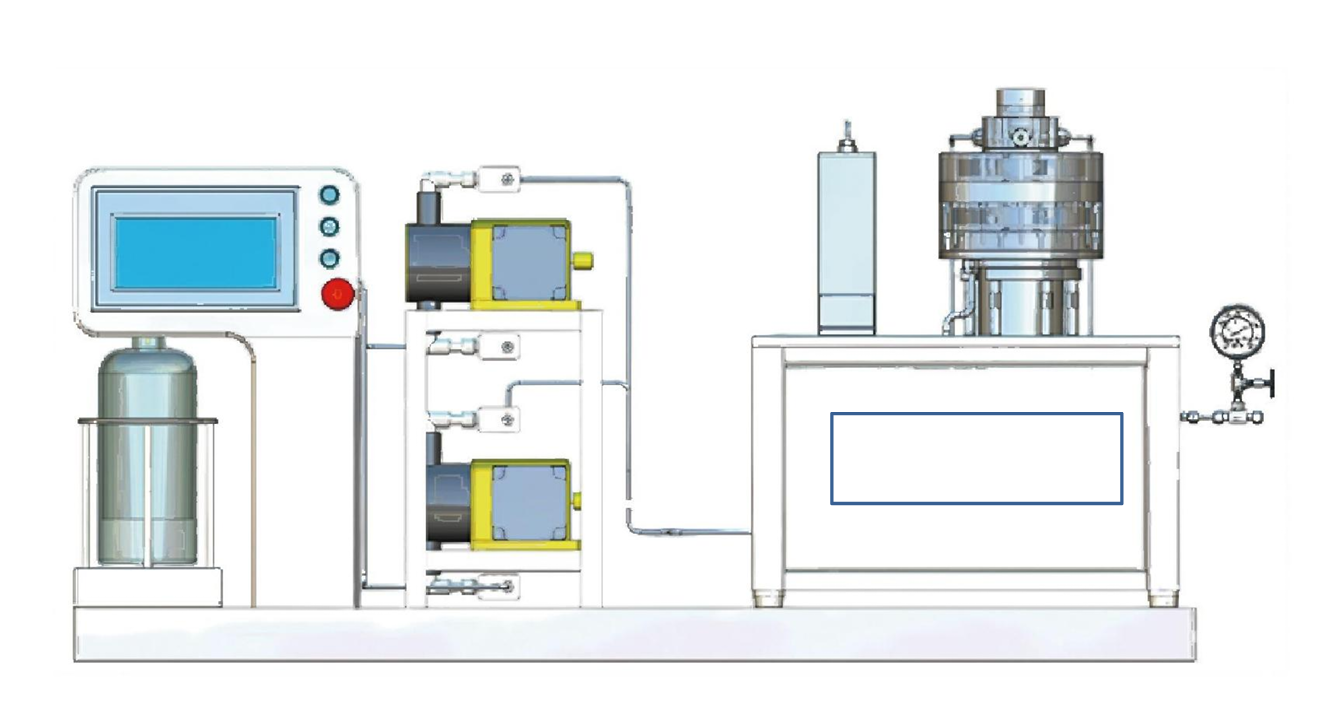

YMC continuous flow microreactor uses a unique internal structure toform rapid turbulentmaterials, which can improve fluidtOWotinternamixing, enhance mass transfer and heat transfer, and is suitable for multi-phasereactions and reactions under hiah-risk or harsh conditions.According to different scenarios Providing one-stop customized services aims toshorten reaction time,reduce resource waste,improve productquality and purity, eliminate safety risks, reduce environmental pollution, and achieve seamless scale-up from laboratory to industrial production.

Features:

The reactor has a small volume and a liquid holding capacity of 10~1000ml;

Large specific surface area, high transfer rate, short contact time, and few by-productsMade of stainless steel 316L, acid and alkali resistant, corrosion resistant, optional silicon carbide, Hastelloy, glass and other materialsHigh flux, plate reactor flux ≥10L/min;

Flow is stable, fluctuation ≤0.1% (pure water test)High working pressure, slicon carbide and alass materials can reach 2.0MPa. stainless steel or other metals can reach 10MpaThe operating temperature range is -70℃~200℃(optional 300'C);

It has high safety and a large amount of heat can be removed in time to ensure that the reaction temperature is maintainedwithin the set range, minimizing the possibility of accidents;

Solid-liouid reaction can be achieved, materials are mixed evenly, and complete reaction can be truly achieved through particlesand powders with a diameter of <0.1mm.

Classification:

Dynamic micro-reactor

High shear structure;

Suitable for reactions involving viscous liquids or the participation or generation of solids;

The stirring impeller shears the material at high speed, resulting in high uniformity and stability of the product;

Efficient mixing, forming micro-nano particles, enhancing reactions, and preventing blockage.

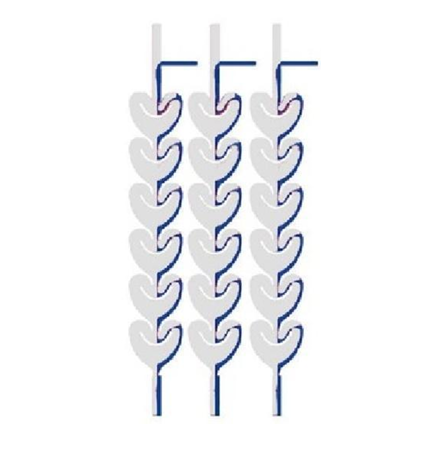

Static microchannel reactor

Manufactured using precision processing technology;

With channel sizes ranging from 10 to 1000 μm;

High mass transfer efficiency, good heat transfer efficiency, and precise automatic control;

Small reaction volume, minimal scale-up effect;

High throughput, good mixing effect, more economical.

Advantages:

Efficient mass transfer and heat transfer

Easy to scale up production

Precise process control

High safety

Multi-functional integration

Environmental protection and economy

Application:

Pharmaceutical intermediates, drug synthesis, fine chemicals, pesticide chemistry, specialty chemicals, consumer goods industry, nanomaterials, pharmaceutical formulations, polymer modification, etc.

Processes:

Reactions

Dynamic Microreactor

Static Microreactor

Delivery

Liquid: Metering Pump

Solid: Loss-in-Weight Weighing

Gas: Pressure Delivery

Measurement

Flow Meter

Weight Sensor

Liquid Level Meter

Supporting

Temperature: Integrated High and Low Temperature Machine

Post-processing

Centrifugation and Filtration

Extraction and Distillation

Principles:

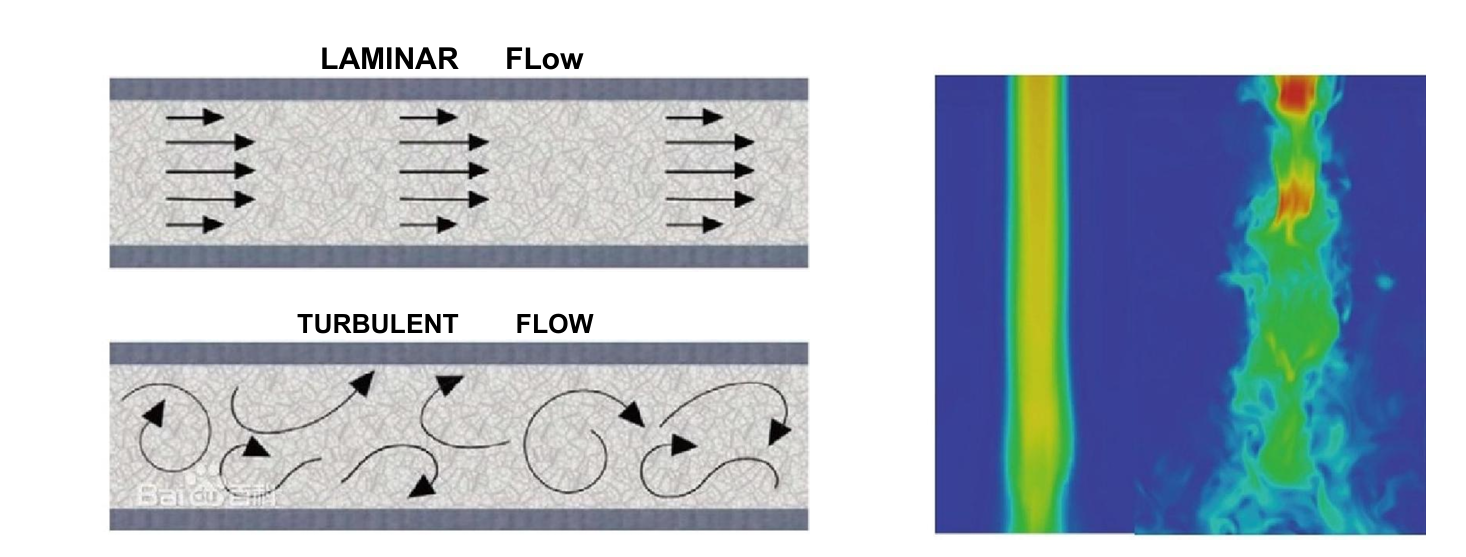

The mixing power of microreactors comes from turbulence.

Laminar flow and turbulent flow are characteristics of fluid motion. When a fluid flows, if the trajectories of the fluid particles (generally varying with the initial spatial coordinates x, y, z over time t) are regular smooth curves (with the simplest case being a straight line), this motion is called laminar flow. Motion without this property is called turbulent flow, and it has better heat transfer and mixing effects.