Reactor Internals Manufacturer for Petrochemical & Fine Chemical Plants

Reactor Internals & Process Equipment Solutions

We specialize in high-efficiency reactor internals and custom process equipment, precision-engineered to fit your exact operational envelope.

Hydroprocessing reactors in the refining and petrochemical industry require precise designs. Ekaislot has developed strong expertise in manufacturing and designing reactor internals, earning recognition from major licensors, oil companies, and EPC contractors.

Hydroprocessing reactors in the refining and petrochemical industry require precise designs. Ekaislot has developed strong expertise in manufacturing and designing reactor internals, earning recognition from major licensors, oil companies, and EPC contractors.

Tower Internals

We design and fabricate reactor and column internals, including liquid and vapor distributors, collectors, support grids, trays, demister pads, and packing supports. Each assembly is tailored to your media, temperature, pressure, corrosion profile, and plot space limits with documented materials and qualified weld procedures for full traceability.

Pressure Vessels

Throughout the entire manufacturing process, we adhere to stringent quality control procedures. Our pressure vessels are capable of withstanding extremely high internal and external pressures and are suitable for a wide variety of application scenarios.

Thin Film Evaporator

Continuous duty for sensitive or viscous media. We focus on stable film formation, efficient heat transfer, service-friendly seals, and inspection points that keep maintenance predictable.

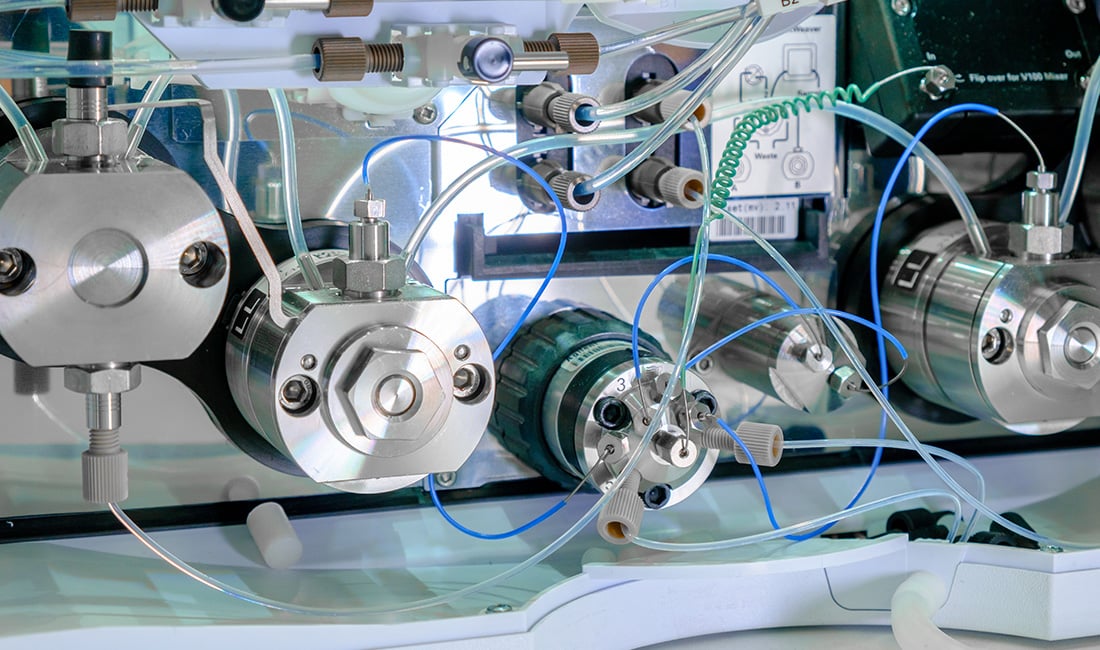

Pilot Plant

Co-develop pilot and demo units to de-risk scale-up. Skid-mounted and instrumented, with clear interfaces for utilities, controls, and data capture—ready for commissioning and iteration.

Agitated Nutsche Filter Dryer

Integrated filtration, washing, and drying in one closed vessel. It minimizes manual handling, reduces operator exposure, and keeps production stable and predictable.

Industries & Solutions for Reactor Internals

and Separation Systems

We align internals and equipment to the realities of each sector—temperature/pressure, corrosion, fouling, batch variability, cleanliness, documentation, and footprint.

Petrochemical & Refining

- Challenges: High T/P, corrosive media, reliability pressures, tight shutdown windows.

- Solutions: Reactor internals, high-efficiency separation, revamp-friendly designs, complete QA packages.

- Outcome: Steady yields, predictable start-ups, and easier maintenance.

Fine Chemicals & New Materials

- Challenges: Variable batches, selectivity, shear sensitivity, strict specs.

- Solutions: Tailored distribution/collection, specialty metallurgy, pilot trials to lock process windows.

- Outcome: Consistent quality with faster changeovers.

Pharma & Biotech

- Challenges: Cleanliness, traceability, cleaning validation, documentation rigor.

- Solutions: Hygienic-leaning details, documented material trace, controlled fabrication and inspection.

- Outcome: Repeatable, auditable runs for regulated environments.

Power & Utilities

- Challenges: Uptime, MTBF, lifecycle cost, predictable spares.

- Solutions: Rugged internals, qualified weld procedures, NDT plans tied to operating duty.

- Outcome: Reliability with fewer unplanned outages.

Ammonia & Fertilizers

- Challenges: Carbamate corrosion, high pressure, foaming carryover, tight turnaround windows.

- Solutions: Corrosion-resistant reactor/column internals, vane/knitted mist eliminators, special-alloy welds and documented QA, optional pilot skids for debottlenecking.

- Outcome: Reduced carbamate carryover, steadier stripper/condenser operation, longer run lengths between washes, more predictable turnarounds.

Environmental & Battery

- Challenges: Complex slurries, fouling, evolving specs, scale-up uncertainty.

- Solutions: Adaptable internals, separation upgrades, pilot skids for iterative proof.

- Outcome: Stable performance as volumes and specs grow.

Industries & Solutions for Reactor Internals

and Separation Systems

We align internals and equipment to the realities of each sector—temperature/pressure, corrosion, fouling, batch variability, cleanliness, documentation, and footprint.

Low-Temperature Solvent Removal Solution for Biopharmaceuticals

Talk to an EngineerProblem to Solve: A biopharmaceutical enterprise needed to perform low-temperature ...

Concentration and Alcohol Removal Solution for TCM Extracts

Talk to an EngineerProblem to Solve: A TCM factory needed to perform concentration ...

Solvent Recovery Solution for Antibiotic APIs

Talk to an EngineerProblem to Solve: An antibiotic production enterprise encountered prominent problems ...

Refining Solution for Biodiesel Production

Talk to an EngineerProblem to Solve: A biodiesel production enterprise faced the problems ...

Recovery Solution for Lithium Battery Waste Electrolyte

Talk to an EngineerProblem to Solve: A new energy material enterprise needed to ...

Regeneration Solution for Waste Lubricating Oil

Talk to an EngineerProblem to Solve: A waste lubricating oil regeneration enterprise in ...

Reactor Internals & Process Equipment Manufacturer

Ekaislot specializes in reactor internals and process equipment for demanding operating conditions. Starting from your process, we co-design and manufacture to help plants increase throughput, uptime, and safety.

We have extensive experience fully complying with the stringent specifications of licensors such as UOP, Axens, Topsoe and Lurgi, ensuring smooth approvals and seamless project execution.

- 0+Years

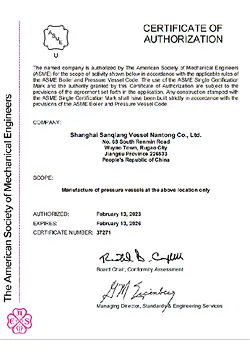

ASME U Certification

- 0+

Listed Companies Partnered

- 0+

Global Projects Delivered

- 0%

RT on Critical Welds

COOPERATION STEPS SECTION TEXT

How We Deliver: Co-Design to Compliant Release

Every phase is gated by documentation and formal reviews. You see the plan, the risks, and the decisions before we cut metal.

Deep Experience & Leadership for Industry Innovation

With extensive industry experience, Ekaislot proactively embraces transformation and reform, consistently leading technological advances and driving industry integration and innovation.

Empowering Diverse Industries

Leveraging Ekaislot’s extensive experience in traditional sectors and collaboration with leading universities, we proactively enter emerging industries such as new energy, biopharma, and environmental technology, driving sustained innovation with solid technical reserves.

Enhanced Project Delivery

From initial co-design to final delivery, Ekaislot integrates our engineering expertise and manufacturing precision to ensure every project is reliable, efficient, and compliant with the highest standards.

Our Expert Team

Three specialists covering process & safety, mechanical systems, and manufacturing—supporting reactor internals and process equipment projects end to end.

Trust Center: Certifications, QA Documentation & Compliance

Design & Manufacturing Standards

Pressure equipment to ASME U / GB 150 D-Class, built and released under controlled documentation procedures.

Certifications

ASME U & GB 150 D-Class pressure vessel standards; ISO 9001 (Quality), ISO 14001 (Environment), ISO 45001 (Occupational Health & Safety).

QA Documentation on Release

Complete documentation package including ITP, WPS, PQR, MTRs, NDE, FAT—with revision control and traceable sign-off.

Third-party Verification

Defined hold points with third-party witness and audit support as required.

Case Highlights for Reactor Internals and Process Equipment

Explore our reactor internals and process equipment deliveries to see proven approaches you can apply next.

Partners & Qualified Customers

Authorized partner and customer logos are shown below. We only display brands with written consent.

Start Your Project

Whether you need reactor internals, a thin film evaporator, a pilot skid, or separation internals, we’ll align scope, milestones, and compliance early to make delivery predictable.

BLOGS

Expert Articles on Reactor Internals Professional Knowledge

Find deep insights into the design, manufacturing, and performance of reactor internals. Our expert-written articles cover the latest innovations, material technologies, and market information.

February 4, 2026

Application of Continuous Flow Reactors in High-Risk Processes

According to the list of high-risk processes published in the “Emergency Notice

February 4, 2026

Application Progress of Continuous Flow Microchannel Reactors in the Pharmaceutical Industry

The core advantages and driving factors of continuous flow technology

Continuous Flow

February 4, 2026

Catalytic Reforming Process Key Equipment and Operational Efficiency

Catalytic reforming plays a crucial role in refineries worldwide. This article will

February 4, 2026

Continuous Flow Microchannel Reactors in the New Materials Industry 1

Technical advantages and industry value:

As a revolutionary innovation in the field